Seven Steps of Lockout/Tagout Procedures

Every day there are several accidents at workplaces worth where the worker doing some maintenance or service work and machine started unexpectedly and harm the worker. All such types of incidents can be prevented by adopting an effective LOTO at our workplace. In this article, we will discuss the standard procedure of the LOTO procedure.

Lockout Tagout (LOTO) is a procedure or control that ensures the isolation of all types of energy resources to avoid unexpected starts while doing maintenance or service work is going on. The energy types under LOTO are listed as under;

- Electrical Energy

- Mechanical Energy

- Hydraulic Energy

- Pneumatic Energy

- Chemical Energy

- Radiation Energy

- Thermal Energy

The standard procedure for lockout/Tagout is divided into seven steps to understand and execute effectively. These steps are listed as under;

- Preparation

- Shutdown

- Isolation

- Lockout/Tagout

- Store Energy check

- Isolation Verification

- Release from Lockout/Tagout

STEP # 1 Preparation

In the preparation step, the authorized person does a risk assessment of the area where LOTO is intended. Identify all types of hazards which can be encountered during maintenance or service work. Identify, energy source, and type which is going to shut down. Communicate and coordinate with relevant departments and people to ensure their backup during shutdown of the energy source. Document all pre-shutdown findings and prepare action plans.

STEP # 2 Shutdown

The shutdown is the first practice step after planning is completed, in this procedure the machine or system is undergone shutdown process which includes gradually slowing and stopping of mechanical parts, taking backups of the tasks to stop and stored in backup files in computer-operated machines and other can be cooling off the hot objects.

In the case of oil and gas industries where LOTO is applied when fuel tanks are subjected to cleaning the shutting off the supply valve of the tanks can be taken as a shutdown step.

STEP # 3 Isolation

The next step is the isolation of the machine or equipment which is being subjected to serving or maintenance. Isolation is a physical activity and it can be done in many ways depending on the type of machine or equipment. Few examples of isolation are listed as under;

- The fuel tanks are isolated by inserting blind flung between the supply line and tank entry point

- Turning off the power breaker

- Removal of the revolving belt between machine and motor

- Disconnect the electric fuse/plug

- Insertion of Safety pins

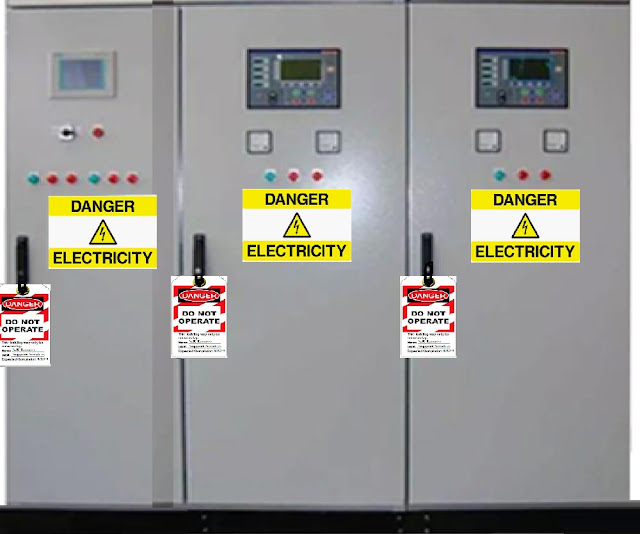

STEP # 4 Lockout/ Tagout

The most important and crucial step of the whole LOTO procedure is STEP # 4 because of this step delegates responsibility and accountability to the authorized person and other people who are involved in this task. One of the energy sources is isolated and prepared for the work. Then the authorized person lock out the isolated part of the machine with special devices list as under;

- All-Purpose Cable Lockout

- Adjustable Ball Valve Lockouts

- Valve Lockouts

- Ball and Ring Hitch Lock

- Niagara Safety Stubby Lockout

- Safety Lockout Hasp

- Push Button Lockouts

- Universal Circuit Breaker Lockout

One the lockout device in-place than tag out of the device is done and the features of tag out are as under;

- Name of Authorized person with signature

- Timeline of Lockout

- Contact Number of Authorized person

- Warning and don’t open Signs

STEP # 5 Store Energy Check

Even if the Lockout and Tag out is done the machine or equipment still needs to be gone through STEP five because the residual emery in the machine or equipment is still dangerous for the workers. To cope with residual energy “the Store Energy check” step is taken.

The store energy can be check-in many ways few examples list as under;

- Venting of fuel tank before start maintenance work

- Removal of residual current by the RCD device

- Neutralization of machine by static current neutralization device

- Cooling of burner

- Time delay in case of a radioactive source

STEP # 6 Isolation Verification

The isolation verification step is the last step of lockout and tag out before starting the maintenance or service work of the respective machine or equipment. This step is performed by an authorized person and technical team by re-ensuring all machines are shut down, isolate, lockout/tag-out, and check the store energy has been managed or released.

After isolation verification, the working team has given work-permit to enter into the working area for the maintenance or serving work.

STEP # 7 Release from Lockout/Tagout

As the LOTO is a closed-loop procedure and according to it the palming should be done by considering the box up of the task. This can be done by the release of the machine or equipment from Lockout/Tag-out. Once the technical team declarer the machine and equipment service has been done and everything is in place. The authorized person takes a risk assessment of the lockout/Tagout and ensures no new hazard/risk originates. Once, all parameters checked the lockout/Tagout of machine or equipment is released and follows rest steps in reverse fashion.

The fuel tanks are isolated by inserting blind flung between the supply line and tank entry point

ReplyDeletehttps://www.aimvisionsafety.co.in/iso-audit-training/